About us

2015

SwitchWeld began to develop a portable, mobile welding cobot incorporating welding technology, motion planning and a high quality robot arm.

2016

The SwitchWeld System was developed and implemented for the most demanding welding applications (Navy Shipbuilding, Energy power sector, civil structures) with systems in continuous weld use.

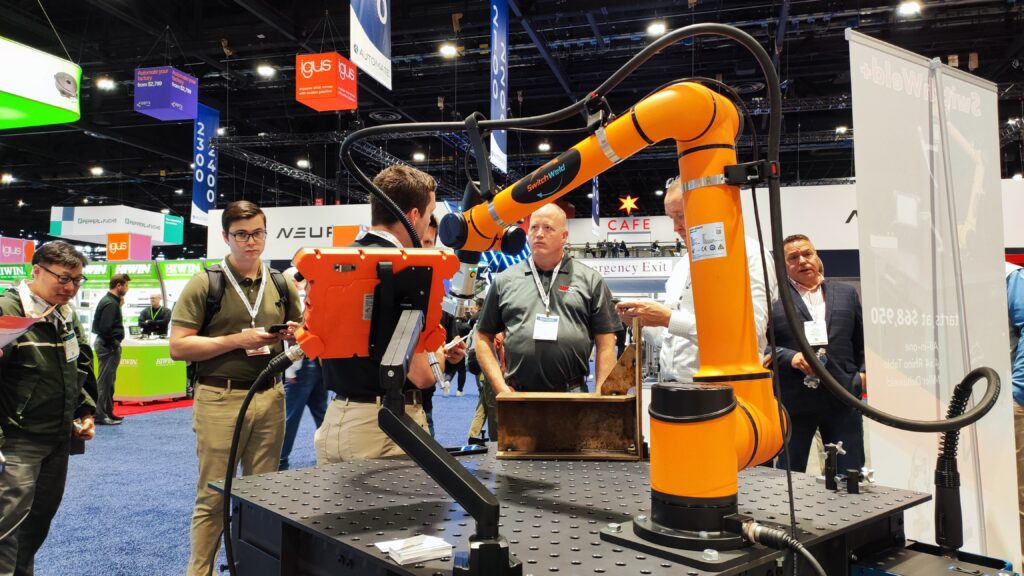

2018

The first commercial version of SwitchWeld was demonstrated at Fabtech, 2018. Picture this, a Fabtech show with ONLY 1 welding cobot displayed – the orange welding cobot now known as SwitchWeld™!

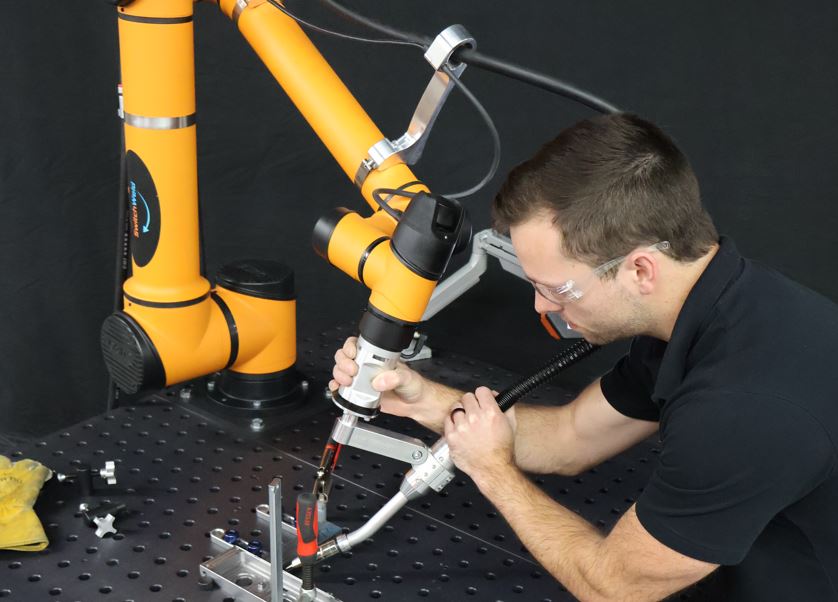

Precise and Easy

Our vision of that first welding cobot was revolutionary. The offer was “pendant-free” weld teaching. The welder could do the majority of the weld teaching right at the torch. A 6 DOF joystick allows for precise fine-tuning of the torch tip resulting in the ultimate smooth and precise weld trajectory. With the best trajectory blending technology, SwitchWeld makes complex welds simpler than ever.

Design for the future

SwitchWeld hold many patents in cobot welding (frankly, the majority of US cobot welding patents), and this technology is found in every switchweld arm. Because of this tight collaboration between weld tool developer and cobot manufacturer, Switchweld systems have the fastest control loop feedbacks offering the best weld motion control for today and future AI-powered welding machines.

Optimize Your Production Line &

Automate with Confidence

Say goodbye to inefficiencies and inconsistencies. Our advanced cobot welding solution brings unparalleled accuracy and speed to your manufacturing process.